The intake manifold market for exotic motorcycles is a very competitive one where styling and functionality are front and center to its enthusiasts. Only a handful of large manufacturers historically have offered these complex products given their significant barriers of entry (i.e. tooling costs) to manufacture such products.

With 3DE, its uniquely integrated prototype/traditional manufacturing pathway supports rapid short run part fabrication for even the most complex components that can easily stay within a cost justified budget!

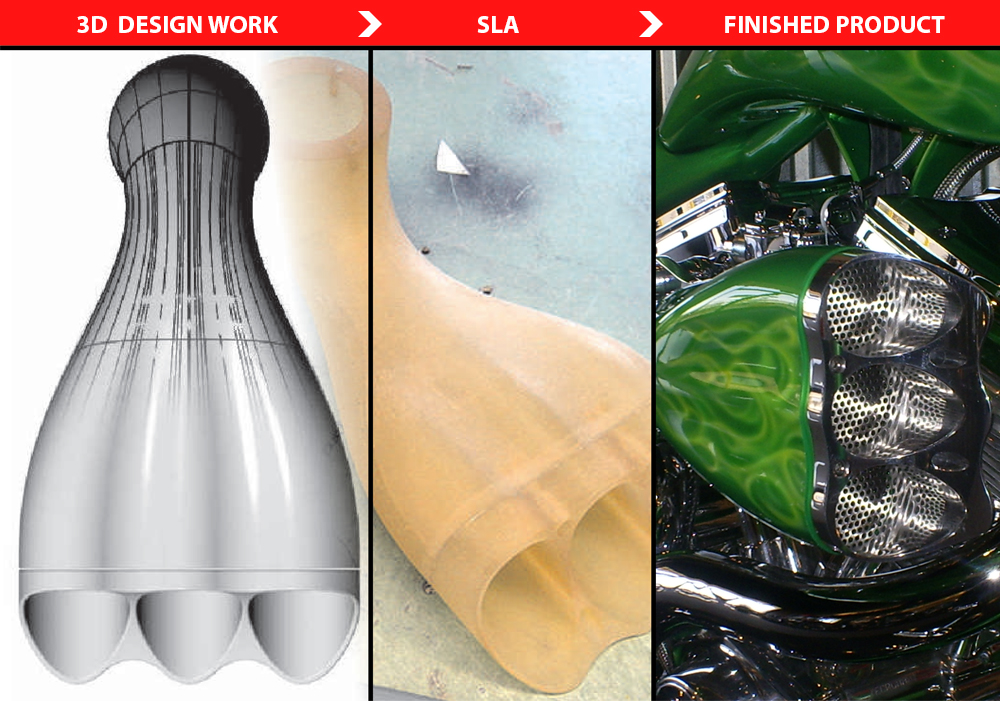

The manifold referenced herein is a professional grade investment cast aluminum part that essentially bi-passed the use of traditional wax die tooling which drastically reduced time and money. Using a method called QuickCast 3DE is able to forgo tooling while still fabricating this complex part in a precision investment cast process. This unique MFG process also includes other rapid manufacturing steps to allow this project to successfully meet the customer’s needs. As an example, the steps to complete this manifold project included the following:

1. Design and Engineering

2. SLA Design Verification (Prototype Process)

3. QuickCast Services

4. Investment Cast (performed by a 3DE vendor)

5. Part Finishing including Anodization, Paint, and Screen Art

6. Final Inspections

7. Ship to Customer

Time Table: 6-Weeks from Authorized PO

Pricing: 1/10 Cost versus Traditional MFG Methods Used

100 Percent Customer Satisfaction!